Understanding the Methyl Methacrylate Resin System

Methyl methacrylate monomer (MMA) is used to create a vast array of materials. Its readily polymerizes to form high molecular weight homopolymers and copolymers.

Okay, so what’s that look like in your life? It’s commonly used in shatterproof glass replacements, safety glazing, plumbing components, and lighting fixtures and displays. You’ll also find it in textile finishes, packaging floor polishes, construction material, and metal and foil coatings. Its chemical make-up allows it to be used diversely. MMA is a monomer that’s a building block for acrylic-based polymers. Polymers are used in many everyday applications in the home or industrially. Either way, they impact our lives on very personal levels—in installations focused on safety and lighting to protection and adhesive needs.

Thermoplastic

As seen in its name, thermoplastic is a plastic, which means it is pliable. Heat (hence, thermo) is what helps shape and mold plastics into the solid end-product they become. The end-product can take on many forms—from pliable, soft plastics with adhesive qualities, to hard smooth-finished solid forms like tubes (PVC pipes) or containers.

A thermoplastic polymer is made up of long, unlinked polymer molecules, generally with a high molecular weight. Because the molecular chains are unlinked, they rely on other interactions for desired outcomes.

Why Color-Safe® Is Different: Our Chemistry

Color-Safe® is a proprietary formula that uses methyl methacrylate (MMA) as its foundational element. While MMA is a better product than thermoplastic, other suppliers of MMA have jumped on the bandwagon with promises of high performance. However, they do not use the high-quality raw materials used in Color-Safe® , therefore, cannot claim the same superior performance benefits of Color-Safe® . MMA comprises a portion of our proprietary formulation, which when combined with our advanced chemistry, creates the superior functionality of Color-Safe®. For instance, Transpo®’s proprietary chemistries—which include MMA—provide better weather resistance, less odor, and increased outdoor life for the product and application.

Color-Safe® Specialty Applications

As the name suggests, Color-Safe® employs the use of bright, highly visible colors—which come in Federal Highway Administration (FHWA)-approved colors and can be custom-created to make unique, vibrant designs, specialty markings, or logos—to increase appeal while improving safety.

Color-Safe® , the durable pavement marking material, fits into Tranpso’s portfolio of state-of-the-art safety products with its wide-spread use on any high-traffic areas where safety, visibility, durability, and longevity is vital, such as:

-

Highways

-

Roadways

-

Airfields

-

Bus Lanes

-

Crosswalks

-

Pedestrian Safety Areas and Walkways

-

Bike paths

-

Parking installations for retail malls, public parking for cities and towns

-

General industrial

Setting the Standard for Safer Roads

Markings must remain vibrant to be a safety feature. The contrasting colors of custom-designed crosswalks alert drivers and can significantly reduce the number of pedestrians injured due to vehicular accidents at crossings. But visibility is not their only function, especially when used on high-traffic areas and crosswalks.

Color-Safe® MMA-based area markings are known for:

-

High durability

-

Increased wet-night visibility

-

Skid resistance

-

Optimal color stability

-

UV resistance

Transpo®'s Color-Safe® MMA marking material is not only one of the most durable markings in the industry, but it can be applied in cold weather, extending the marking season. Due to their high durability, color stability, and high-definition colors, MMA road markings cost less in maintenance and material costs over the extended lifecycle of the markings. Color-Safe® is capable of full cure in a wide range of temperatures, down to 40°F, and adheres to both concrete and asphalt surfaces. MMA symbols and striping develop a strong bond to existing MMA; another reason that Color-Safe® is a viable, superior alternative to thermoplastic markings.

This increased functionality makes Color-Safe® MMA a preferred choice of transportation and safety officials as the optimal material for special-use lane marking material.

Color-Safe® MMA Features and Advantages

-

Variety of standard and custom colors; aggregate types and sizes available

-

Durable skid-resistant surface

-

Excellent vibrant color retention

-

Easily customizable designs for high-visibility safety and identification purposes

-

Fast cure in a wide range of temperatures (40°-100° F); lengthens the marking season

-

Low life-cycle cost (6 – 10 years; requires simple refresh vs. re-application)

-

Strong adhesion to concrete and asphalt surfaces; minimized cracking and bubbling

-

Installations can be modified, depending on traffic usage, for superior skid resistance and drainage

-

Safe, easy application vs. cumbersome process: mix-and-apply vs. hot, potentially uneven application and risk of burn

-

Save time: set-up and installation time is quick and easy with Color-Safe®

-

Color-Safe® frees up work crews—time and money—so they can complete other projects as well

-

Expert customer support from Transpo®

Problems with Thermoplastic

Heat: As discussed, thermoplastic requires the application of heat, whether while applying in liquid form, or the use of a blow torch when using pre-forms. One concern regards the materials used: alkyd and hydrocarbons cannot be mixed in the melter. If there is a material change, the melter must be thoroughly cleaned prior to using the other material. Other considerations are the weather elements such as wind chill, which may result in raising the temperature of the thermoplastic to compensate, though may cause overheating that may char the material. Other problems that can result, for both the people applying the thermoplastic, or for the longevity and durability of the application are:

-

Risk of injury

-

Working with hot plastic is very tricky and must be applied at the proper temperature—precision and timing is also required for proper thickness, and can be difficult to master

-

If a sprayer is used for application, it may result in heat loss, which may adversely affect the bond between the marking and the substrate; the thickness may also be compromised, as it is directly affected by the speed of the applicator

Application: In addition to the logistic concerns above, there can be issues during the application process, once thermoplastic is applied, or there may be problems that begin immediately or become problematic over time.

-

Grooves and scratch marks

-

Pinholes

-

Bleeding

-

Cracks caused from a variety of variables.

-

Hollows and hairline cracks on the top film caused by the uneven dispersion of the tiny beads. Cratering can also occur on these irregular road surfaces and is caused when the application speed is too fast

-

Irregularities on the line surface cause rough irregularities on the cross direction, which occur from the poor deposit of the thermoplastic from the applicator shoe

-

Poor retroreflectivity at night can occur either overall or in a specific area

-

Peeling

-

Color changes (from white to dirty white, and yellow to dark green) is due to the thermoplastic overheating while preheating

There are a number of problems that often occur with thermoplastic applications, limiting their useful lifecycle, that range from cracking and cratering to delamination and discoloring. These all compromise the safety of the material’s original purpose, requiring extensive training and set-up and expensive re-application to remedy.

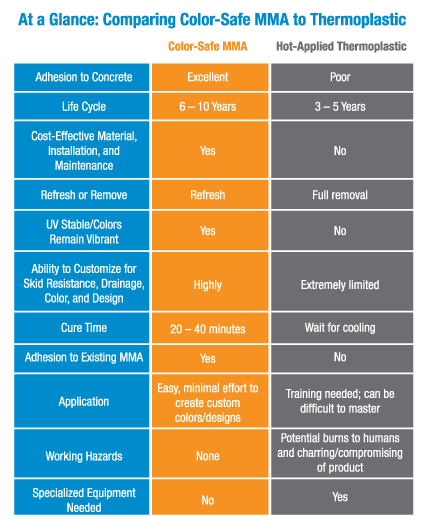

This chart sums it up: Color-Safe® is manufactured for superior quality, performance, and reliability and delivers that by providing a more cost-effective, durable, vibrant, customizable, and safer pavement marking solution for you and your crews.

There’s more to this discussion that is covered in our comprehensive eBook, “Why Choose Color-Safe MMA over Thermoplastic?” Curious about the problems thermoplastic can cause you for your next pavement marking installation … and how to avoid them with Color-Safe? Download it now to find out.